Pipe Facing machine for Pipeline Construction

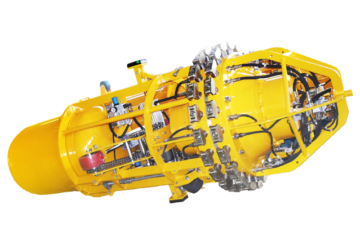

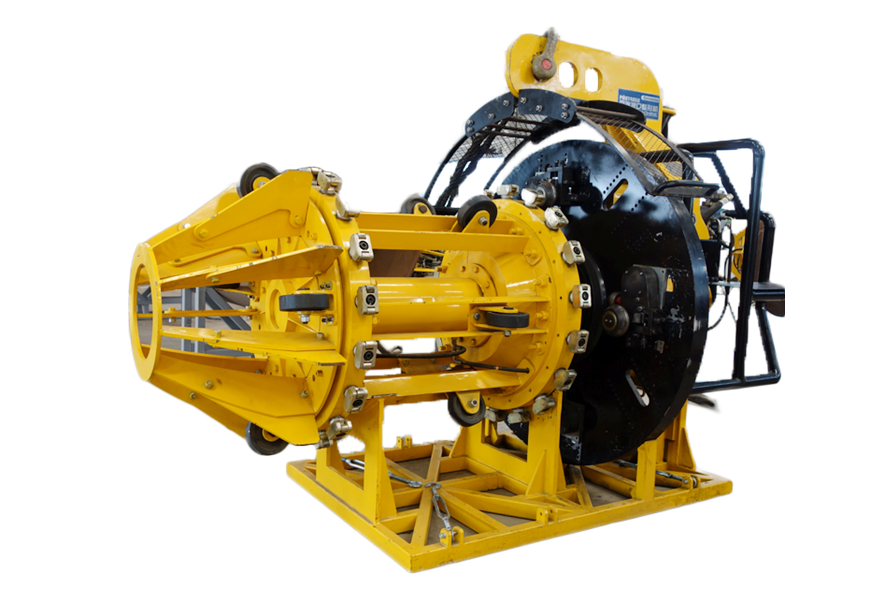

Pipe Facing Machine consist of a diesel-powered or electric-powered hydraulic unit and the hydraulic powered facing machine itself, which is responsible for the shape-cutting of pipe ends.

Both electric and diesel drive Hydraulic Power Units can be supplied for Arctic use down to -50°C or tropical area with higher temperature rating of 50°C.

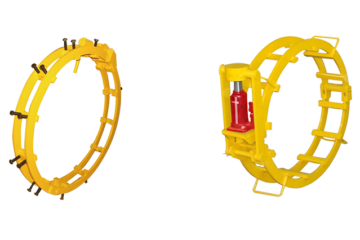

Structure of Pipe Facing machine

Pipe Facing machine: Main Drive And Feed Drive System, Tool And Guide Wheel System, Operating Platform, Tensioning Device

Power Unit for Pipe Facing machine: Engine, Instrument Panel, Hydraulic Oil Radiator, Power Hose, Oil Tank, Hydraulic Pump

Pipe Facing machine |

Power Unit for Pipe Facing machine |

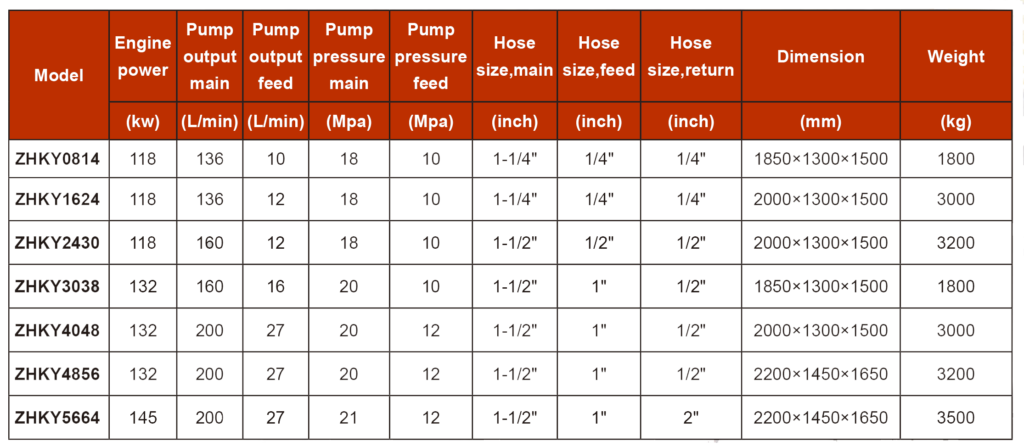

Technological Parameters of Pipe Facing machine

Technological Parameters of Pipe Facing machine

Technological Parameters of Power Unit for Pipe Facing machine

Features & Benefits of Pipe Facing machine

- The facing machine has two major parts, the clamping section and the machining section.

- 8” to 64” pipe diameter facing machine can be available.

- Machining any kinds of bevels accurately.

- High speed beveling, high efficiency and energy saving.

- Big cutting volume, average using time for each pipe end is 1 to 2 minute.

- Hydraulic unit driving by diesel engine be used for onshore p ipeline construction.

- Hydraulic unit driving by elect rical engine be used for offshore pipeline const ruction.

- The clamp section has two sets of hydraulically powered clamping shoes that are designed to work equally and simultaneously. The machine is locked precisely and durably to the pipe end by expanding the clamp shoes inside the pipe during the entire pipe beveling process.

- The machining section consists of a rotating faceplate with four or six tool holders each holding tungsten carbide cutting tools. The tools can be set to machine a wide variety of bevel designs and wall thicknesses. Each tool holder may cut a different bevel angle simultaneously.

- The tool-holding fixture guides and holds the cutting tools. Each tool holder is equipped with guidance rollers that are pressed against the inside pipe surface to provide precise height compensation during the facing process. In addition, each tool holder is equipped with a wire brush ensuring that all cutting residuals are neatly removed from the pipe’s surface.

- Both front and rear section of the expander unit is equipped with circumferentially arranged polyethylene guidance rollers that prevent the pipe surface and coating from being damaged when the facing machine is inserted or pulled out.

- Pipe-End Facing Machines work at rotary speeds ranging from 30 to 100 rpm, depending on the pipe diameter. Beveling a pipe end takes between 3 and 10 minutes, depending on the wall thickness and the specifi c type of bevel to be created.

- Pipe-End Facing Machines come with a tubular-frame structure and stand allowing comfortable transportation. A steel frame protects the machine during rugged use on construction sites. The protective cover over the rotary cutting wheel provides maximum safety for the operator.

- Hydraulic Power Units are used to power Pipe Facing Machines.

- These units consist of a power drive unit, hydraulic reservoir, main pump, feed pump, main and feed pressure relief valves, pressure gauges, filters and all necessary hoses, fittings, and quick disconnects needed.