Pipeline Induction Heating System

According to the relevant requirements of the welding process regulations, the welding joints of large diameter long-distance pipelines should be preheated before assembly welding, and the preheating temperature is generally required to be ≥ 60 ℃. When welding long-distance pipelines in extremely cold areas at -20 ℃, due to the low ambient temperature, it is easy to cause the cooling rate of the weld metal to be too fast, which affects the welding quality and mechanical properties of the weld metal. Therefore, the preheating temperature should be appropriately increased during construction. The preheating temperature should be increased by 20-30 ℃ compared to the warm season construction, reaching 80 ℃ or above. At present, the Pipeline Induction Heating System is all installed outside the pipeline for welding heating, suitable for welding operations in extremely cold weather trenches. However, during the assembly welding in the trench, due to the large fluctuation of the pipeline, it is not possible to use an internal alignment tool for alignment, and only an external alignment tool can be used for alignment. After installing the external connector on the pipeline, the Pipeline Induction Heating System cannot tightly adhere to the outer wall of the pipeline and cannot be heated. In this case, the Pipeline Induction Heating System can be used to preheat the welded joint before aligning, and then an external aligning device can be used for pipeline assembly. However, by the time of formal welding, the temperature of the welded joint cannot meet the temperature required by the welding process specification, resulting in poor welding quality.

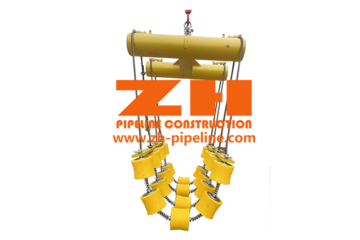

Pipeline Induction Heating System With Flexible Coil

Features and Benefits of ZH Pipeline Induction Heating System With Flexible Coil

- The Pipeline Induction Heating System With Flexible Coil is pushed to the area inside the pipeline that needs to be heated for heating, changing the preheating of pipeline welding joints from traditional external heating to heating from the inside of the pipeline. This not only meets the installation of external welding joints in extremely cold weather, but also meets the requirements of welding joint preheating. The two tasks do not affect each other and can be operated synchronously, saving construction time and improving the overall welding construction efficiency.

- With the help of Pipeline Induction Heating System With Flexible Coil has the advantages of uniform heating, fast heating speed, and high heating efficiency compared to traditional manual flame welding preheating methods.

- This ZH Pipeline Induction Heating System With Flexible Coil is an IGBT inverter and uses DSP for fully digital precise control, ensuring that the IGBT always operates in the ZCS switch state under various working conditions.

- ZH Pipeline Induction Heating System With Flexible Coil has fully air-cooled structure reduces system losses and completely eliminates equipment failures from the water system.

- ZH Pipeline Induction Heating System With Flexible Coil has Comprehensive restrictive protection measures ensure continuous and safe operation of equipment under various working conditions.

- ZH Pipeline Induction Heating System With Flexible Coil has Non polar power capacitors improve the lifespan and safe operation capability of equipment.

- ZH Pipeline Induction Heating System With Flexible Coil DC side chopper voltage regulation or filtering circuit improves the system power factor.