Working principle of ZH Pipe Facing Machine for Pipeline Construction

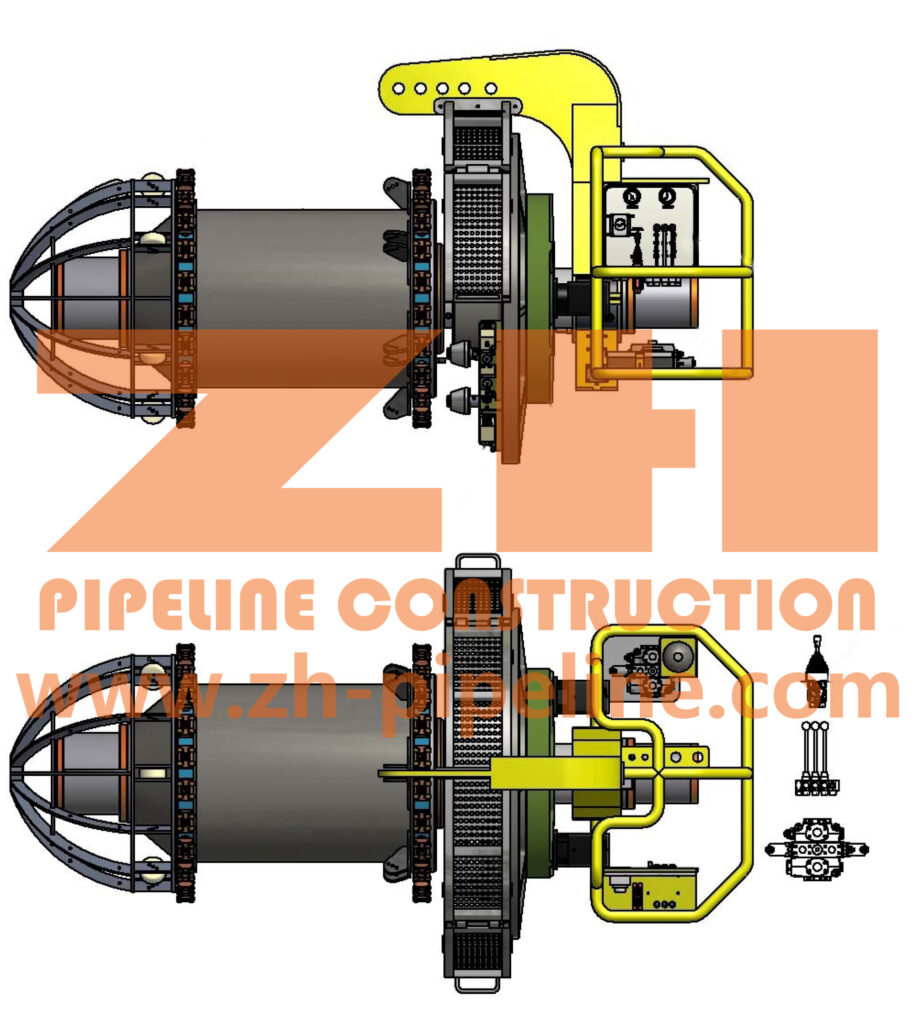

The hydraulic drive unit ZH Pipe Facing Machine for Pipeline Construction is a hydraulic motor – drives a pair of large modulus reduction gears through a large reduction ratio reducer to achieve the rotation of the cutter head. And through the oil cylinder connecting plate installed at the rear of the spindle, the servo feed oil cylinder is fixed on the spindle, and the servo feed oil cylinder is directly connected to the spindle moving sleeve, driving the rotating cutter head to achieve axial feed.

Pipe Facing Machine for Pipeline Construction

Structure of ZH Pipe Facing Machine for Pipeline Construction

Pipe Facing machine: Tensioning Device, Guide Positioning Part, Main Transmission And Feed Transmission System, Tool And Guide Wheel System.

Power Unit for Pipe Facing machine: Engine, Instrument Panel, Hydraulic Oil Radiator, Power Hose, Oil Tank, Hydraulic Pump.

Pipe Facing Machine for Pipeline Construction

Features & Benefits of ZH Pipe Facing Machine for Pipeline Construction

- Adopting Cummins 6BT four stroke, turbocharged, water-cooled direct electric starting diesel engine.

- ZH Pipe Facing Machine for Pipeline Construction adopts a three stage filtered air filter.

- ZH Pipe Facing Machine for Pipeline Construction adopts a diesel engine as the power source, the diesel engine is placed in a welded frame through a shockproof bracket, and the hydraulic pump is connected to the output end of the diesel engine.

- Forming tools of ZH Pipe Facing Machine for Pipeline Construction can meet various groove forms are installed on a rotating cutter head, which is equipped with a total of 4 sets of tools, which can meet the processing requirements of different forms of pipeline grooves.

- During the cutting process, the support box is fixed and the large gear moves along the axis of the small gear. Complete the feed motion of the cutting.

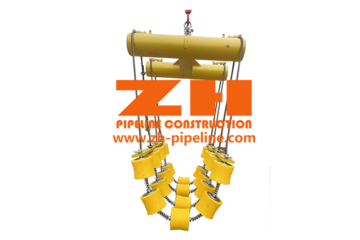

- ZH Pipe Facing Machine for Pipeline Construction tightening device is equipped with two sets of tightening devices, and the front and rear two rows of tightening mechanisms are achieved by double rod hydraulic cylinders through two-stage torque amplification to achieve the expansion and contraction of the shoe.

- The tool holder of ZH Pipe Facing Machine for Pipeline Construction realizes the floating of each cutting tool during the cutting process through the guide wheel and spring support mechanism, thereby meeting the impact of the non roundness of the pipe mouth on the accuracy of the blunt edge of the groove after cutting.

- The main back pressure closed drive is adopted in the main motion system, which greatly improves the smoothness of motion in situations with significant load changes, greatly improving the quality of cutting, and maximizing the use of engine power. This allows the cutter head to have a large cutting torque and speed during cutting, greatly improving work efficiency of ZH Pipe Facing Machine for Pipeline Construction.

- The lifting crossbeam in the support box is equipped with an anti flying and trampling iron chip cover, making on-site operations safer and more reliable. And the support box is equipped with a hydraulic multi way directional valve, hydraulic control valve, oil separation block, and oil pipe. The oil inlet circuits between the individual valves in the multi way directional valve are parallel, and the slide valves can be operated independently. The four handles can be pulled to drive the opening and retraction of the expansion shoe, the rotation of the cutter head, and the fast forward or backward movement of the cutter head. Easy to operate and high reliability.