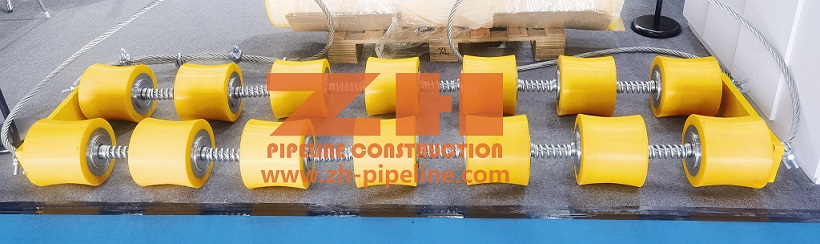

Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction

ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction

ZH Analog Vietz Roller Cradle is used to move the welded pipeline into the Lower trenches. With the help of the Pipelayer, the robust rollers are coated with plastic, so that damage to the PE insulation is excluded. Due to the ball bearing of the rollers an optimal running behavior of the Pipe strands guaranteed. In pipeline construction, The working environment is very complex, there is extreme desert weather, extremely cold working environments, and construction in swampy environments and etc, Therefore, the quality of the ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction and its adaptability to extreme environments have a significant impact on the safety and work efficiency of pipeline laying into the trench process.

Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction

Technological Performance of ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction

Load Capacity:4t-49t

Diameter Range:6 inch-56 inch(168mm-1524mm)

Safety Factor:5

Roller Materials: Composite Materials

Bearing: Swedish SKF

Working Temperature: Minus 30 degrees to 70 degrees

Advantages of ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction

- All the Rollers of ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction can replace original German Vietz Roller Cradle for Pipelaying.

- ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction choose the steel wire rope from well-known manufacturers to ensure the high-performance of Pipeline Roller Cradle on work site, reduce the accident rate of pipe laying.

- Due to the extreme working environment of pipeline construction is usually carried out, the working environment has a significant impact on the Roller Cradle for Pipelaying in Pipeline Construction. In order to design a Roller Cradle for Pipelaying in Pipeline Construction with a wider range of applications, ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction has designed a unique structure, roller coating process, and coating thickness. In extremely cold and hot working environments, the coating of the Rollers of ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction will not fall off or separate from the roller bearing. And the layer thickness of the Rollers of ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction is 3-4 times than others Roller Cradle for Pipelaying in Pipeline Construction, ensuring high load-bearing capacity, high wear resistance, and elasticity of the hanging basket.

- ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction has optimized structure, high strength bolt fixed structure. The structure of Pipeline Roller Cradle can be disassembled for easy transportation. The structure of Pipeline Roller Cradle can be installed very quickly in the work site.

- ZH Pipeline Roller Cradle has special roller connection type, which makes the connection between the rollers more tight, better sealing performance, so that the roller is not easy to be affected by the sand environment at the work site when in various extreme working conditions.

- As we know, the load-bearing capacity of the Roller Cradle for Pipelaying in Pipeline Construction depends on the material and welding process of the hanging beam. Therefore, the ZH Analog Vietz Roller Cradle for Pipelaying in Pipeline Construction uses high-quality seamless steel pipes as the hanging beam, and the overall welding process ensures the strength of the welding. It provides a solid safety guarantee for the work of pipeline trench laying.