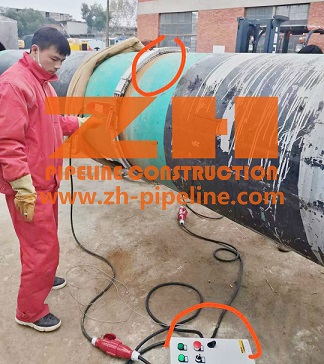

During the on-site construction of long-distance pipelines, the preheating and tempering of pipeline nozzles before welding, as well as the preheating and tempering treatment before anti-corrosion operations, require Induction Coil Heating. When workers start root welding on pipelines, the starting temperature of the welding interface is required to reach a very high temperature, usually above+100 ℃, and the temperature during filling welding and cover welding is required to be above+80 ℃. Therefore, we need to preheat and heat up the welding interface before starting the welding work; And it is required to maintain temperature at the welding interface during the welding process to ensure welding quality.

Induction Coil Heating for Pipeline Welding Work

Working principle of Induction Coil Heating for Pipeline Welding Work

The Induction Coil Heating for Pipeline Welding Work can quickly heat up the pipeline welding joint in a short period of time during the process preparation stage, and after the pipeline welding operation starts, the heating can continue to run simultaneously with the welding.

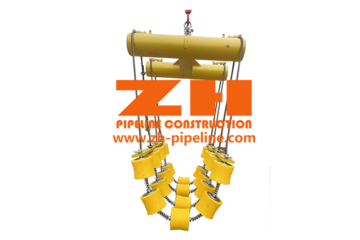

Structure of Induction Coil Heating for Pipeline Welding Work

ZH Pipeline Construction Coil Heating for Pipeline Welding Work uses stainless steel as the structural framework, stainless steel sheathed heating cable as the heating element, and high temperature resistant reinforced Aluminium silicate fiber rope as the internal insulation material. The outer protection is equipped with a flexible stainless steel shell.

Induction Coil Heating for Pipeline Welding Work

Technical Parameters of Induction Coil Heating for Pipeline Welding Work

Pipe size:16-60 inch

Heating width:400-600mm or by the requirement of Cucstomer.

Working range:-40—200℃

Efficiency:3-15 min

Induction Coil Heating for Pipeline Welding Work

Features & Benefits of ZH Induction Coil Heating for Pipeline Welding Work

- When Induction Coil Heating for pipeline heating, it can run simultaneously with welding work, improving the efficiency of welding work.

- Induction cables are resistant to high temperatures and extreme cold environments, providing ZH Induction Coil Heating has a wider range of applications.

- The high heating efficiency and fast heating speed of ZH Construction Coil Heating have greatly improved the efficiency of pipeline construction to a certain extent.

- The length and width of ZH Induction Coil Heating can be customized according to customer requirements.

- Easy to operate, compact, and sturdy in structure.

- To ensure safer and more reliable operation, the ZH Induction Coil Heating for Pipeline Welding Work has high electrical insulation strength, and the ZH Induction Coil Heating for Pipeline Welding Work has a leakage protection switch to ensure operator safety.

- Easy maintenance, maintenance free.

- Easy store, Store in a cool and dry place to avoid accidental impact.

- Low energy consumption, welding junction electric heating belt is a pure resistive load, installed in the field welding generator in combination with inductive load, can improve the power factor of the generator, improve efficiency, and fully utilize the abundant backup power of the field welding generator, so there is no need to increase energy and costs.

- The main material is stainless steel, which is resistant to high temperature corrosion.

- ZH Induction Coil Heating for Pipeline Welding Work equipped with a quick connector, the power connection is convenient and fast.

- ZH Construction Coil Heating for Pipeline Welding Work is equipped with intelligent temperature control components, which can achieve automatic temperature monitoring start and stop.