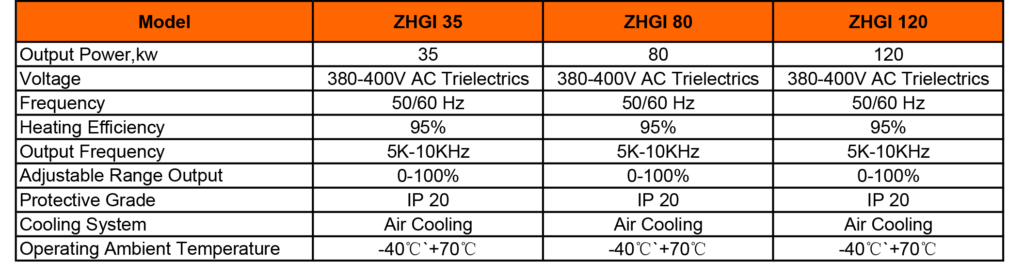

Technical Parameters- Induction Heating System for Pipeline Construction

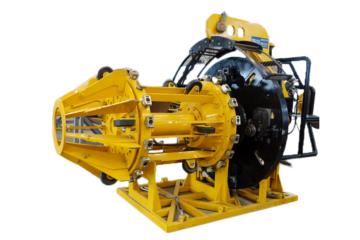

Induction Heating System for Pipeline Construction

Features & Benefits- Induction Heating System for Pipeline Construction

◆ IGBT Inverter

ZH Induction Heating System for Pipeline Construction adopts advanced technology IGBT inverter, with the help of IGBT inverter, ZH Induction Heating System provides high pressure while satisfying stable, high speed output to adapt to a variety of complex, extreme working conditions.

◆ DSP – Digital Signal Process

ZH Induction Heating System equiped with DSP-

Digital Signal Process, with the help of DSP-Digital Signal Process, ZH Induction Heating System provides digital precision control, the multi-channel input analog signal is converted into digital signal, easy operation and ensures stable power output under various extreme working conditions.

◆ Wide Range of Application

ZH has Induction Heating System for Pipeline Construction a variety of operation modes and control modes, operator set a variety of performance parameters of on worksite, so that the product can meet the requirements of special pipeline construction technology.

◆ Air cooling

ZH Induction Heating System adopts air cooling structure to ensure heat dissipation and cooling.

◆ High Operational Safety

ZH Induction Heating System for Pipeline Construction adopts Multiple safety protection devicesoperational safety to the Induction Heating System works without failure for a long time, so that personnel and equipment will not be lost due to accidents.

◆ High Operational Reliability

The high redundancy design of the core components of ZH Induction Heating System for Pipeline Construction greatly improves the service life of the ZH Induction Heating System, while ensuring that the system can be carried out 24 hours uninterrupted safe work.

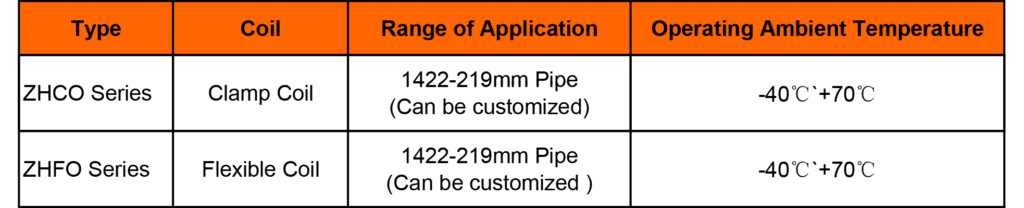

Technical Parameters – Coil Inductor for Pipeline Construction

Technical Parameters – Coil Inductor for Pipeline Construction

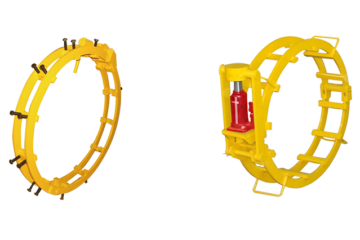

Features & Benefits – Coil Inductor for Induction Heating System of Pipeline Construction

◆ The Clamp Coil Inductor for Induction Heating System of Pipeline Construction is designed to heat the pipe after the welding process in order to make the pipe cutback surface ready for the joint coating.

◆ The Clamp Coil Inductor for Induction Heating System is hydraulic operative for open and close which makes it easy and precisive operation during the use.

◆ Durable structure and induction cable gives a long time service no need maintainance.

◆ The flexible inductors is used for reserve the temperature between the welding passes as well as different diameters of pipes or when meet the bended pipe or elbows, the heating cables is applied for the heating purpose.

◆ All the Clamp Coil Inductor for Induction Heating System can be quickly exchanged from the induction heating system for the different task.

◆ Like the Ring Coils Clamp Coil Inductor for Induction Heating System also can be used for two sizes through the adjustment of the adapters.

◆ The heating process is started by a simple push of a button, and all the control can be done by the remote device which is along with the operator and this makes the heating system is very convenient to use.

◆ All heating equipments are air-forced cooled and don’t need any external cooling equipment. This feature allows having a handy structure and a very reliable system.