Induction Heating System for Pipeline Heating

In modernization Pipeline Construction, most of Pipeline Construction with big diameter, in order to increase the welding work and Anticorrosive Coating work quality and work efficiency. ZH Induction Heating System adopts electromagnetic induction heating technology, Induction Heating Generator and Coils cooperate with each other to heat the pipe. Induction Heating System is an important equipment in modern pipeline construction technology.

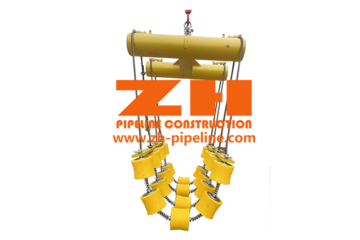

Structure of ZH Induction Heating System for Pipeline Heating of Pipeline Construction

Technical Parameter Induction Heating System for Pipeline Heating of Pipeline Construction

Series: ZHGI 35, ZHGI80, ZHGI120

Diameter Pipeline:

Power:3-Phase Line Powered

Voltage and Frquency:380V/50 HZ, 415/50HZ,460V/60HZ,

Cooling System: Air Cooling

Working Temperature:-40℃ to +50 ℃

Application of ZH Induction Heating System for Pipeline Heating of Pipeline Construction

Advantages of Induction Heating System for Pipeline Heating of Pipeline Construction

ZH Induction Heating System for Pipeline Heating of Pipeline Construction adopts Automatic frequency conversion control, Frequency changes automatically, so that the system can adjust its frequency according to different working conditions to adapt to different working conditions.

ZH Induction Heating System for Pipeline Heating of Pipeline Construction can be used in -40 ℃ extremely cold working conditions and +55 ℃ extremely hot working environment.

ZH Induction Heating System for Pipeline Heating of Pipeline Construction can be used in air humidity less than 95% working environment.

ZH Induction Heating System for Pipeline Heating of Pipeline Construction can be used in height above sea level 3000m working environment.

ZH Induction Heating System for Pipeline Heating has high speed heating efficiency, ZH Induction Heating System can heats the pipeline with 1422mm diameter from working temperature to 120℃ within 5-10 min.

ZH Induction Heating System for Pipeline Heating of Pipeline Construction can not only ensures the high efficient work, but also has a variety of safety protection design to protect the safety of operators and the safety of the site working environment.