Pipe Internal Pneumatic Line-Up Clamps for Pipeline Construction

Pipe Internal Pneumatic Line-Up Clamps is a device that uses compressed air as the power source to drive, operate and control. It is mainly used in pipeline welding construction. Radial force is generated from the inside of the steel pipe to quickly align the two pipe nozzles to be assembled to meet the requirements of pipeline welding.

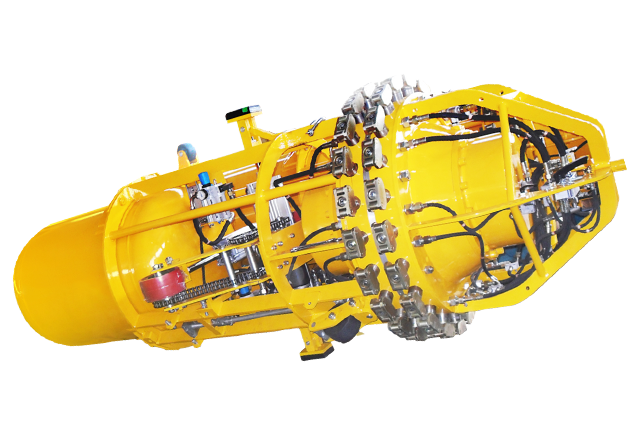

Drive module ZH Pipe Internal Pneumatic Line-Up Clamps adopts American Ingersoll Rand or German Festo pneumatic motor has powerful power and reliable work. The pneumatic part is Japanese SMC. Norgren electromagnetic horn, Fog lubrication. ZH Pipe Internal Pneumatic Line-Up Clamps adopts Movement and brake, Brake and drive work together to improve the safety of operation and the reliability of Internal Pneumatic Line-Up Clamps positioned, Steel roll for moving in the pipe, The Internal Pneumatic Line-Up Clamps is equipped with a braking device, which can control the Internal Pneumatic Line-Up Clamps on a steep slope. Collet ZH Pipe Internal Pneumatic Line-Up Clamps has 2 rows of centering, 8-30 for each centering row. The number of presses in a centering row depends on the size of the Pipe Internal Pneumatic Line-Up Clamps. The Pipe Internal Pneumatic Line-Up Clamps precisely aligns the end face of the pipe through the positioning amplifier and is fixed with the centering line.The collet of the Pipe Internal Pneumatic Line-Up Clamps in the pipeline is equipped with rollers to ensure accurate alignment and stress relief. By placing the clamping head tightly around it, the best stress distribution can be achieved to obtain accurate centering.

Internal Pneumatic Line-Up Clamp for Pipeline Construction

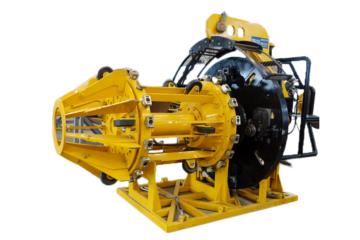

Structure of Pipe Internal Pneumatic Line-Up Clamps

Front cage, mating assembly, electrical assembly, traveling wheel, soft connection, brake assembly, drive assembly, hydraulic oil tank

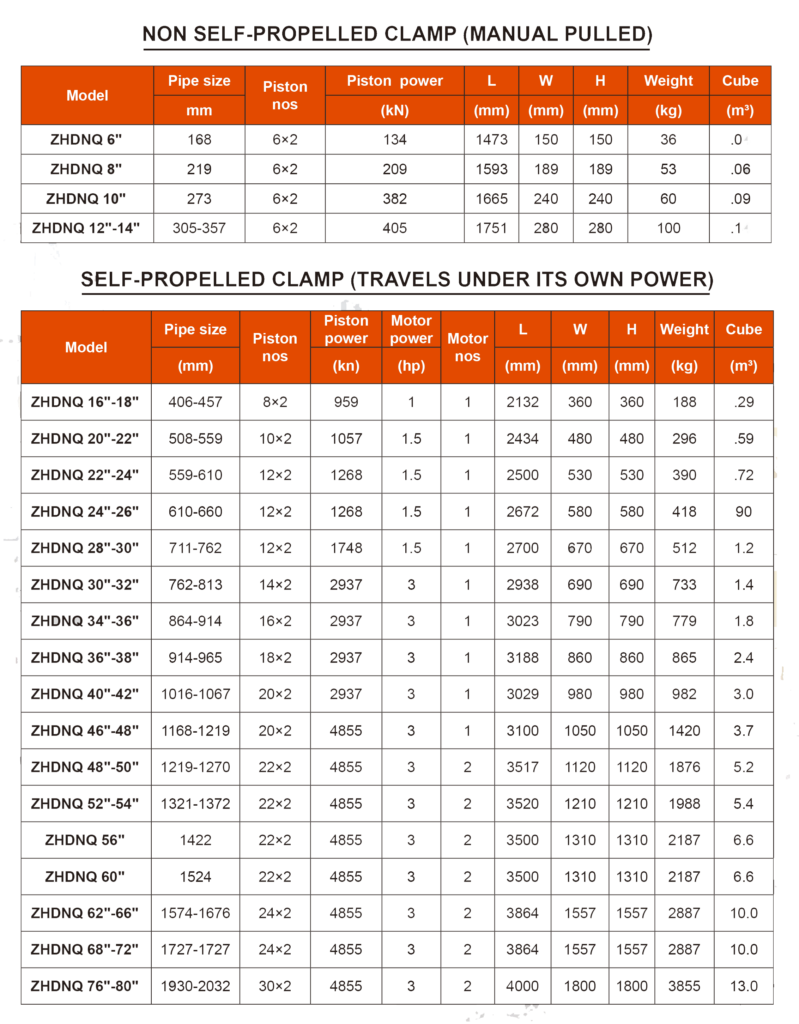

Technological Parameters of Pipe Internal Pneumatic Line-Up Clamps

Pipe Internal Pneumatic Line-Up Clamps

Features & Benefits of Pipe Internal Pneumatic Line-Up Clamps

◆ Dual Control System

ZH Pipe Internal Pneumatic Line-Up Clamps adopts dual control system of operating buttons on the machine and the operating rods with standard length of 13ms.

◆ High Pressure

Max. Pressure of ZH Pipe Internal Pneumatic Line-Up Clamps for Pipeline Construction 1.6 Mpa, and Max. working pressure 0.8 Mpa, Travelling Working Pressure 0.7Mpa.

◆ Air Pressure Regulator

ZH Pipe Internal Pneumatic Line-Up Clamps adopts equipped with compressed air pressure setting regulator and mist lubrication for efficient operation.

◆ Adjustable Roller-Type Expanders

ZH Pipe Internal Pneumatic Line-Up Clamps adopts adjustable roller-type expanders for any wall thickness within the specified pipe size.

◆ Copper Backup Shoe

Copper backup shoe equipped as optional device for automatic orbital welding.

◆ Conversion Kits

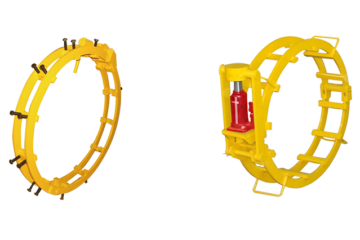

12” and above clamps covers at least two pipe diameters by using of conversion kits.

◆ Motorized Units

Motorized units are available from size 16″ to 80″ while the small sizes are pull traveled.

◆ High Performance

All self-propelled clamps have 20 degree average grade capability with standard equipment of parking brake.

◆ Motorized Units

Motorized units are available from size 16″ to 80″ while the small sizes are pull traveled.

◆ High Travel Speed

ZH Pipe Internal Pneumatic Line-Up Clamps max travel speed 1.3 m/s.

◆ Adjustable Drive and Free Wheel

ZH Pipe Internal Pneumatic Line-Up Clamps adopts adjustable drive and free wheel for different pipe size.

◆ Big Air Tank

ZH Pipe Internal Pneumatic Line-Up Clamps has adequate power for average 4 joints alignment under fast operation are assured by a compressed air tank.