Pipelayer for Pipelaying

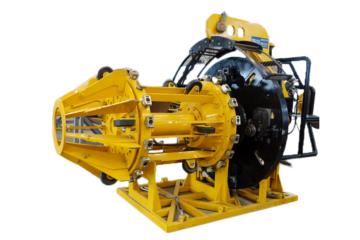

The Pipelayer for Pipeline Construction is an important construction equipment in the construction of oil and gas pipelines, mainly used for the laying, aligning and trenching of large-diameter pipes. It has the characteristics of large lifting capacity and walking with heavy objects.

There are many types of Pipelayer for Pipeline Construction. It can be divided into general Pipelayer, multifunctional Pipelayer and wetland Pipelayer according to the purpose; According to the structural characteristics, Pipelayer can be divided into bridge type pipe hanger, boom type pipe hanger and fixed type Pipelayer.

Structure of Pipelayer for Pipelaying

Engine,Cabin,Boom,Control,Steering System,Counter Weight,Winch,Undercarriage,Electronic Over Hydraulic,Braking And Steering System,Safety Devices.

Pipelayer for Pipeline Construction

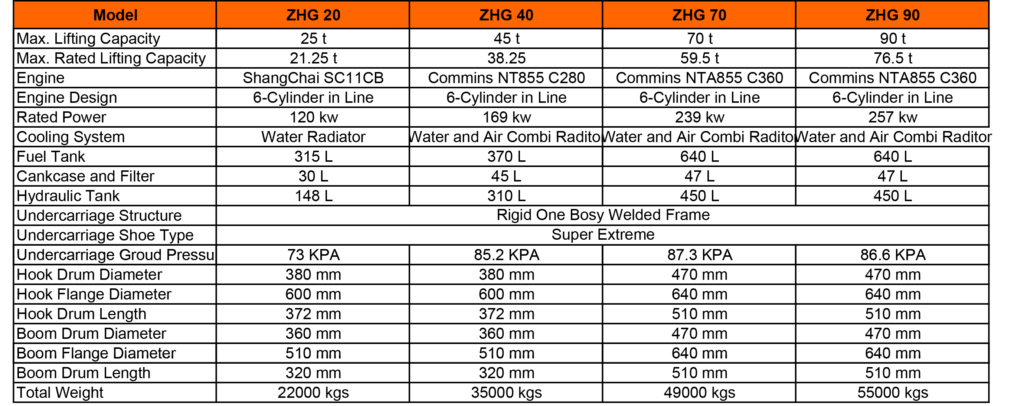

Technological Parameters of Pipelayer for Pipeline Construction

-

Pipelayer for Pipeline Construction

- Features & Benefits of Pipelayer for Pipeline Construction

◆ Engine

The Cummins Engine of Pipelayer for Pipeline Construction direct injection and turbocharged engine gives sustained power and high torque rise that is required for the more tough jobs.

◆ Cabin

Good visibility to work area and top of the boom with a sky window on the roof, ROPS can be installed as the optional equipment of Pipelayer for Pipeline Construction.

◆ Boom

Tubular A-Frame boom engineered for exceptional support at maximum lift capacity and easy detachment.

◆ Control

Multi-axis, hydraulic joystick allows simultaneous, precise control of the load and booms functions with one hand. Single-Iever, hydraulic remote control valves are used for counterweight and two speed functions. The controls are easy to operate and require minimum operator training.

◆ Steering System

Differential steering system of Pipelayer for Pipeline Construction comes with the advantage of higher maneuverability and enhanced slope capabilities. hydraulic power assisted steering makes operating the machine comfortable for the operator.

◆ Counter Weight

Hydraulically operated, four-bar linkage counter-weight system adds maximum stability and lifting capability. Low, compact design provides balanced weight distribution for optimum operating control and excellent visibility.

◆ Winch

Two independently controlled hydraulic winches drive the boom and hook systems, brake are applied automatically when control lever returned to neutral position.

◆ Undercarriage

Undercarriage of ZH Pipelayer for Pipeline Construction With high stability and low ground pressure, the rigid and boxed frame undercarriage meet the requirement of all type of terrains, giving a dependable and longevity of service in all harsh conditions.

◆ Electronic Over Hydraulic

Freefall system, boom kick-out system and anti-two block plus, Anti-tipping system Prevents tipping by calculating the maximum load that can be lifted.

◆ Braking And Steering System

Dual foot operated steering brakes of Pipelayer for Pipeline Construction with hydraulic booster to reduce operator’s efforts. Brakes are spring applied and hydraulic released. Brakes and steering clutches are interconnected for easy steering. Hand levers are conveniently located on left side of the operator seat.

◆ Safety Devices of ZH Pipelayer for Pipeline Construction.

Free Fall System: When the button is engaged, the load free-falls and then immediately.

Automatic Boom Kick-Out: This system will ensure you will never bend another boom.

Anti Two Block: Sets a minimum distance between the top block and the hook block, preventing collisions between them.

Anti Tipping System: Prevents tipping by calculating the maximum load that can be lifted.分类: Products