Welding Tractor for Pipeline

Welding Tractor for Pipeline Construction chooses famous brand diesel engine as power source, whose vehicle-mounted electricity generating system can supply power of 100/125/160kVA. The generating system uses technics-mature timing belt transmission which features simple in structure, reliable in transmission performance, lubricating-free and long service life.

The chassis is full hydraulic driven that is specially designed for Crawler Pay Welder which has a strong cross country capability that is suitable for execrable site conditions such as soft soil, desert etc.

The customer’s application requirements and operational habits for Welding Tractor for Pipeline Construction have been taken into consideration completely in the design. The attached crane with a good lifting capacity is equipped in the middle of machine, the pulley block can swing within certain range, and it can also ensure wire rope without emerging out the groove when it inclines to certain angle, which suits for uneven working site. Left side is used for the operation area, and providing adequate space for most welding equipment, most of the welding works can be done on this side. The welding spaces are prepared in pairs for customers to install welding machines.

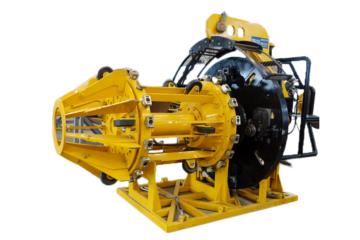

Structure of Welding Tractor for Pipeline Construction

Engine, Generator, Hydraulic System, Undercarriage, Cabin, Crane, Welding Wire Feeder, Rear Equipment Cover ,Manual Cylinder Holder (Optional),Fuel Tank, Space For Air Compressor, Space For Welding Rod Dryer, Space For Hydraulic Valve, Front Welding Machine Space, Electrical Control Cabinet, Rear Welding Machine Space, Maintenance Passage

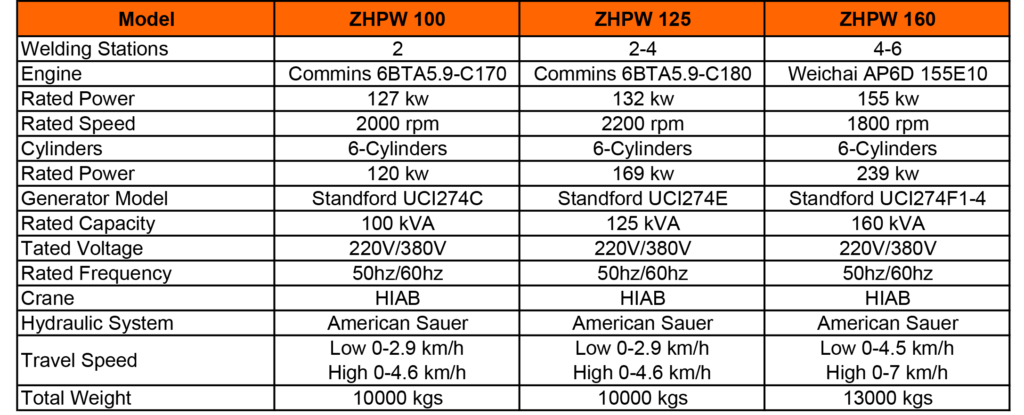

Technological Parameters of Welding Tractor for Pipeline Construction

Welding Tractor for Pipeline Construction

Features & Benefits of Welding Tractor for Pipeline Construction

◆Engine

ZH Welding Tractor for Pipeline Construction Equipped the Cummins 6BTA5.9-C series diesel engine, high quality and easy maintain, ensuring sustained power output for the welding procedure demand. Enlarge cooling system and cold area starter device can be install while using in the tropical or frozen area.

◆ Generator

Through a direct-drive mode from the engine, Stanford generator is employed for the pay welder’s generating system. The generator is brushless maintain free type ensuring a long agility of optimal performance.

◆ Hydraulic System

American Sauer hydraulic system is installed in the Welding Tractor for Pipeline Construction for power both the travelling of tractor and crane operation. Pump is directly connected to the drive train after the engine and generator.

◆ Undercarriage

Hydrostatic driven gives enough power for traveling on even more grade slope of the work site, track counter rotation on the spot give more maneuverable operation of the tractor, high ground clearance and low ground pressure allows working of Welding Tractor for Pipeline Construction in any type of tough ground conditions.

◆ Electrical Cabinet

Power source form the generating system is controlled and distributed at the electrical cabinet. The cabinet of Welding Tractor for Pipeline Construction is water proof and equipped with a big area of shatterproof glass for clear and easy reading of the volt, ampere and frequency meters. Emergency breaker is standard equip of this unit for the people and equipment’s safety.

◆ Enclosed Cabin

Big room space, max glass area gives the operator comfortable operating condition. Lever controls of both the traveling and crane in the cabin, safety switch equipment at the side of the driver’s seat to prevents tractor from running during the generating work.

◆ Crane

The HIAB series hydraulic crane is mounted onto the Welding Tractor for Pipeline Construction for lifting the welding tent and other welding accessories. Crane operation can be arranged both inside and outside the cabin.