Welding Tractor for Pipeline Construction

ZH Welding Tractor for Pipeline Construction has been especially designed according to the requirements of large diameter pipeline constructions. ZH Welding Tractor for Pipeline Construction adopts fully steel tracked chassis and a fully hydraulic closed drive walking system, with strong off-road capability. In addition to being suitable for driving on roads in general areas, it is also suitable for large-scale outdoor engineering construction operations in harsh environments such as deserts, loose soil, and plateaus. It can fully meet various working conditions and operational requirements in pipeline construction.

Welding Tractor for Pipeline Construction

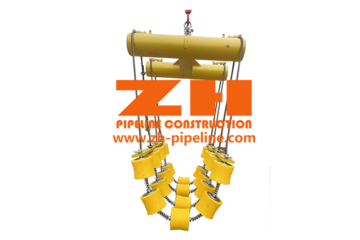

The design of ZH Pipeiline Welding Tractor for Pipeline Construction pay more attention to user’s requirements and operating habits. The middle of the ZH Welding Tractor for Pipeline Construction is equipped with a crane, which adopts a foldable and retractable boom design, with a wide operating range and strong adaptability. The crane can be equipped with a hydraulic winch to ensure the mobility of lifting operations. On the left and right sides of the entire machine, lifting operation handles with the same function are arranged. At the same time, the crane has retractable legs, which, in conjunction with the front and rear legs of the entire machine, ensure the lifting capacity of the crane, making the operation of the entire ZH Welding Tractor for Pipeline Construction safe, user-friendly, and convenient.

Welding Tractor for Pipeline Construction

Structure of ZH Welding Tractor for Pipeline Construction

Undercarriage, Engine, Generator, Enclosed Cabin, Onboard Crane, Hydraulic System, Electrical Cabinet, Optional Configuration, Air Compressor, Drying Box, Gas Cylinder Rack, Electric Welding Machine.

Welding Tractor for Pipeline Construction

Features & Benefits of ZH Welding Tractor for Pipeline Construction

- The ZH Welding Tractor for Pipeline Construction can adapt to various harsh construction environments and ensure project progress.

- Easy maintenance methods and minimal maintenance requirements keep your equipment in good working condition all the time.

- Reliable Engine, ZH Welding Tractor for Pipeline Construction adopts Cummins Engines with strong horsepower and high reliability, six cylinder, 4-stroke, turbocharged, and water-cooled; Small size, high power, low specific fuel consumption, and high reliability. Maintenance can be carried out without the use of specialized tools, making maintenance very simple. Standard air pre filter, extending air filter maintenance cycle, ensuring that the engine can maintain good performance even in harsh environments. Three stage fuel filtration, suitable for low-quality fuel, protects the engine’s fuel injection system.

- ZH Welding Tractor for Pipeline Construction adopts an international brand brushless and maintenance free hair care motor to ensure energy conversion efficiency, the longest maintenance cycle can reach 40000 hours.

- The main circuit of the hydraulic system adopts advanced LS control mode, which can ensure strong power output when walking is needed; When walking is not necessary, it is in a low-pressure zero flow standby state to reduce engine power consumption.

- ZH Welding Tractor for Pipeline Construction multi-functional electrical cabinet is mainly composed of frequency meter, voltmeter, ammeter, leakage circuit breaker, waterproof socket, etc. It has two outputs for 380V and 220V waterproof sockets, and five outputs for 380V circuit breaker control. It also has power indication and safety protection devices.

- Enclosed Cabin, away from the engine, reducing the damage of engine noise to you. A viscous shock absorber is used between the cab and the frame. The seat has the functions of fore and aft adjustment, backrest angle adjustment, and shock absorption support with adjustable load-bearing force. Various control buttons and levers are within reach.